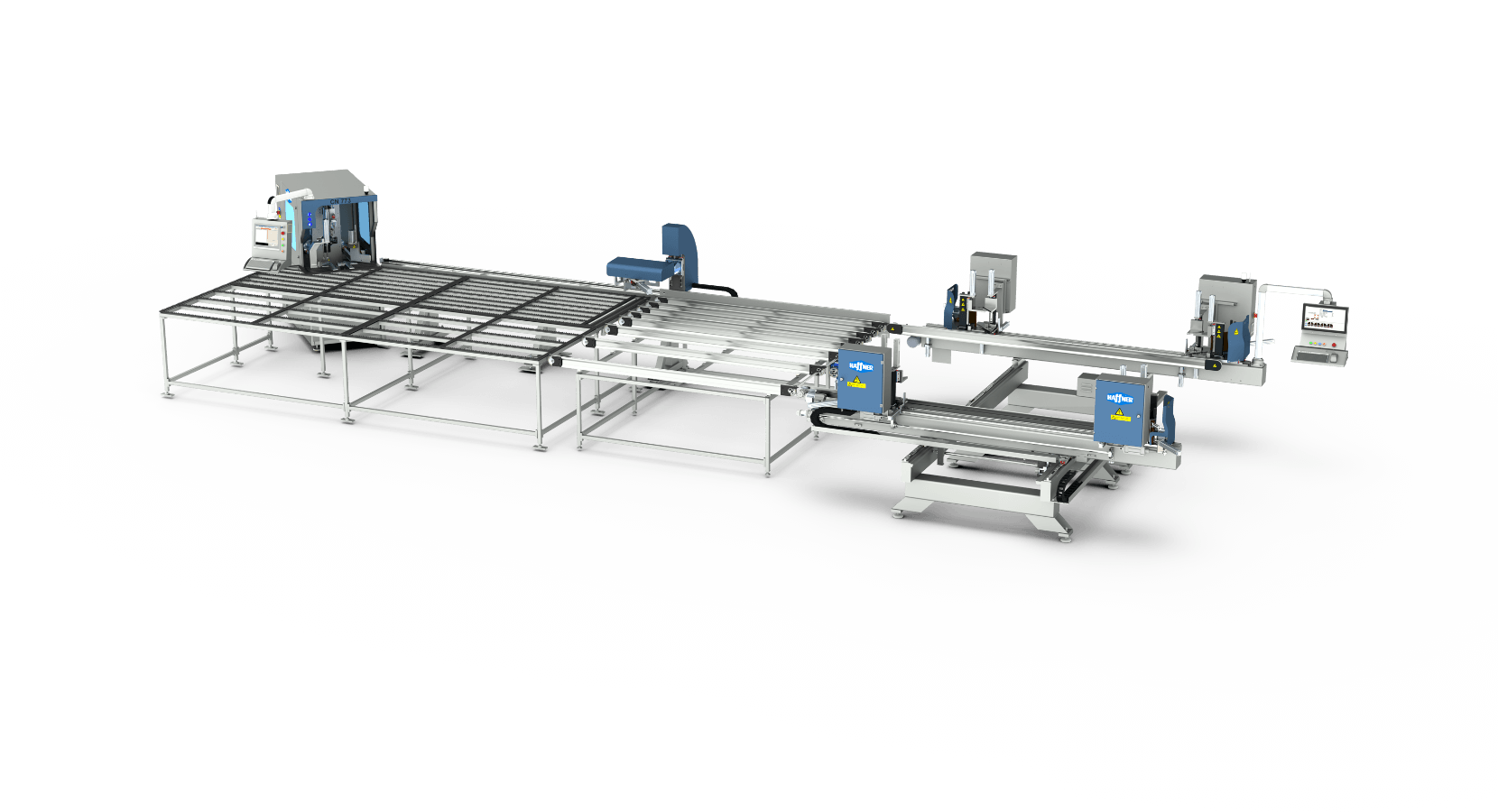

Single Line 2Four Head Welding and CNC Corner Cleaning Line

Single Line 2 is created with the integration of KD 658/20 Four Corner Welding Machine, CK 187 Cooling Station, CK 180 Faster Turning Robot and CN 772 CNC Corner Cleaning Machine. From welding to cleaning, every stages of the profile processing is controlled by the computer.

While the Four Corner Welding machine starts welding a new frame, CN 772 Corner Cleaning Machine can start the cleaning process of the frame. Thanks to the servo motor rotating robot, the frames are rotated quickly and stably and corner positioning is made. (Small frames 1 sec., Large frames 1.5 - 4 sec.) Profile information is automatically transferred from the welding machine. Backlash-free gearboxes are used with hardened rack and pinion gear system that provides precision and durability in the axes.

Service by remote connection method is possible and provides problem detection and solution by connecting to the entire automation system. Data is transferred and automatically backed up via wireless network connection and USB. There is a central lubrication system that facilitates machine maintenance. Rails and transfer systems are specially coated against corrosion.

CK 187 Cooling Station

It takes the welded profiles for necessary cooling stage before transferring them to the turning station for corner cleaning. The cooling time is controlled by the computer on the welding machine.

CK 180 Speed Turning Robot

It works integrated with CN 770/20 CNC Corner Cleaning Machine. It automatically takes the welded frames at four sides to the corner cleaning machine, drives the corners to be cleaned towards the machine and automatically turns the frames.

Optional

Barcode reader

Gasket Pressing System

Automatic 0,2mm and 1,2 mm welding seam restriction settings.