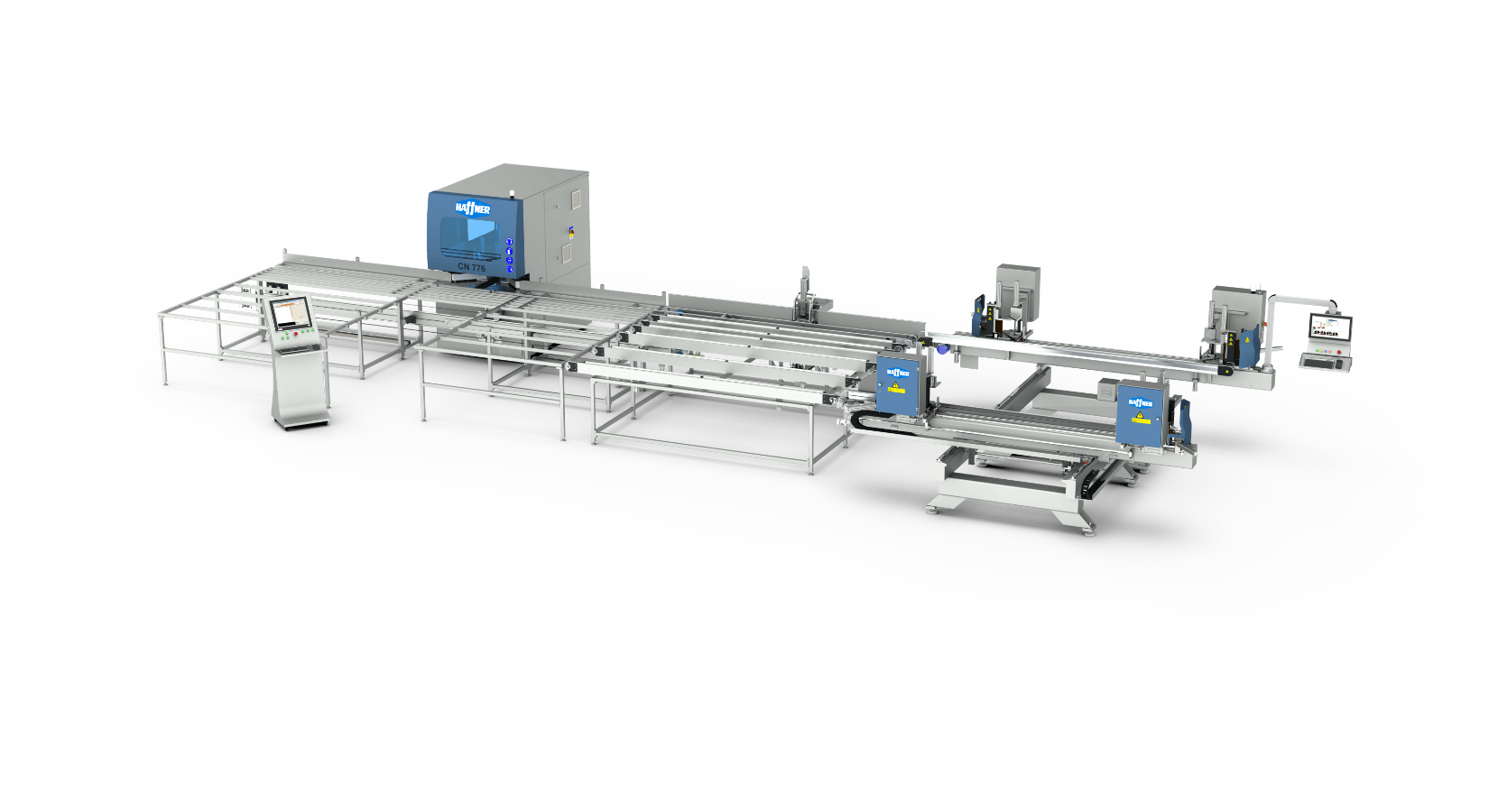

Single Line 3Four Head Welding and CNC Corner Cleaning Machine

Single Line 3 is created with the integration of KD 658/20

Four Corner Welding Machine, CK 188 Cooling Station, CK 176 Turning Station and

CN 776 CNC Corner Cleaning Machine. Computer controlled triple handle drilling and espagnolette

canal milling is processed while the frame or sash is cooling at the buffer

station. CN 776 Corner Cleaning Machine

can start cleaning the corners while the Four Head Welding Machine starts the

welding process. Thanks to the CK 176 turning station, the welded frames are rotated at an appropriate speed and size and cleaned in four corners.

With the movement provided in one direction, faster and more stable rotation is achieved. Profile information is automatically transferred from the welding machine. By online connection to the entire system, remote detection of malfunctions and maintenance is available. Data transfer is available via network and connection or USB storage. Central lubrication system is available to eases the machine maintenance. The transfer rails are specially coated to prevent corrosion.

CK 188 Buffer Cooling Station

Cooling station which transfers the welded frames or sashes from four head welding machine to turning station for corner cleaning. Computer controlled triple handle drilling and espagnolette canal milling is processed while the frame or sash is cooling at the buffer station. Waiting time for cooling is controlled by the computer of the welding machine.

CK 176 Turning Station

It works

integrated with CN 776 CNC Corner Cleaning Machine. It transfers welded frames at four side to the corner cleaning machine in a fast and

stable way. With the carrier clamping system that automatically comes out from

the bottom and automatically turns the four corners of the frame. Separate robot clamping system for loading and unloading stations works with two separate servo axes operating

independently of each other. The four corners of the frame are brought to the

point where the operator will take the frame.

Optional Barcode Reader (AK 002), Seal Printing System (AK

032), 0.2 mm and 1.2 mm automatic welding range selection (AK 052)