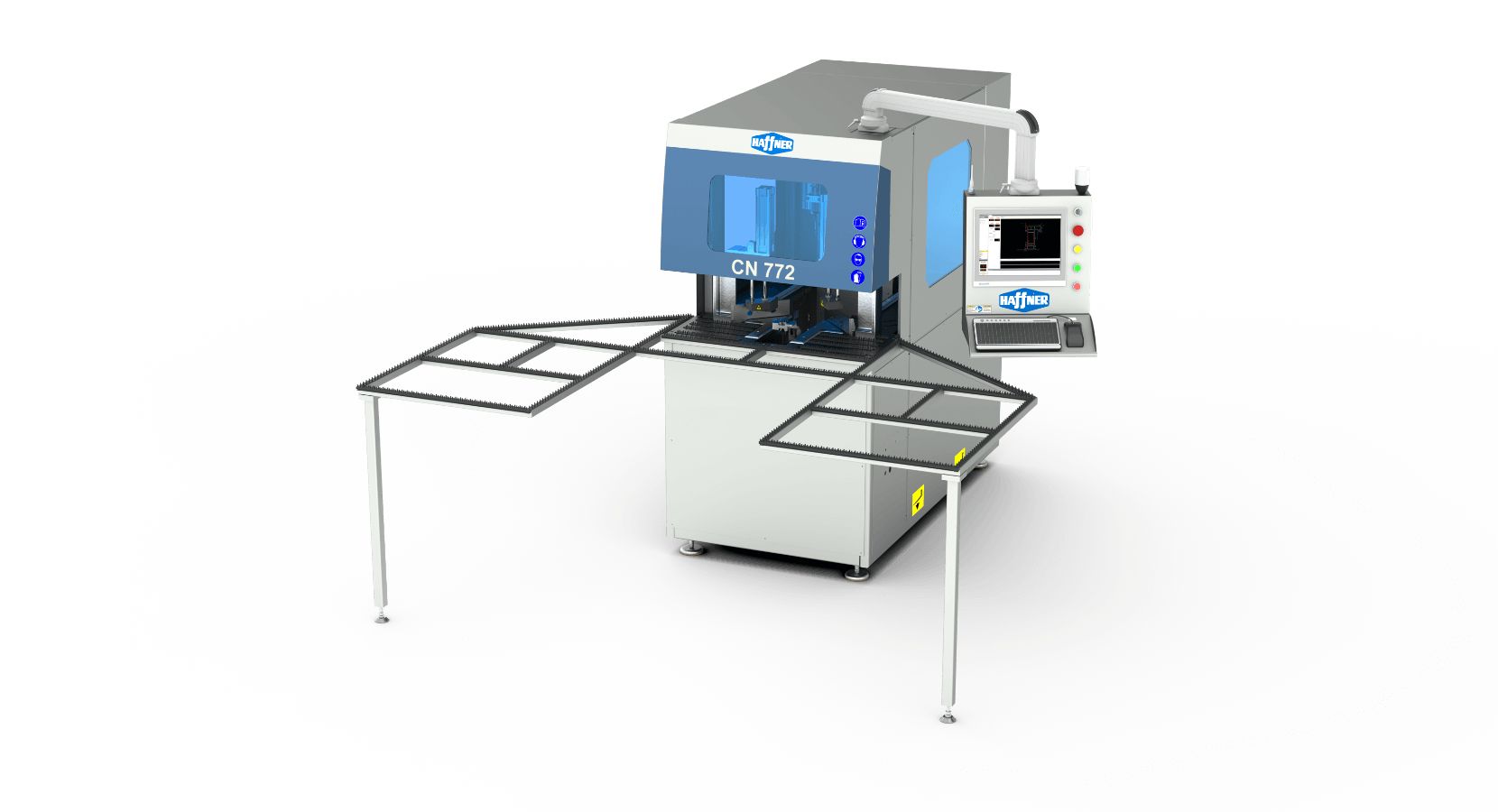

CN 772CNC Corner Cleaning Machinery

4 axis high-speed servo controls enables fast working with high accuracy. Shortens work cycle by simultaneous processing on both lower and upper surfaces of the frame. Delivers ultimate results in corner cleaning by specially designed 11 diff erent tools. It performs automatic cleaning by selecting the white and coated profiles and the profiles with or without gasket from the screen.

CN 772 is equipped with ergonomic operator terminal can be easily moved to every corner around the machine, 15” touch screen, high performance industrial PC with Windows 10 operating system and works without a fan activity between between 0°C - 55°C. Haffner Machinery Software Department enables to create new programs and edit the existing ones easily by using the dxf drawings of profiles on the screen.

Can connect to a single line machine easly. All error messages can be monitored from the screen. User friendly unique interface developed by By online connection to the entire system, remote detection of malfunctions and maintenance is available. The software cleans unnecessary processes and sustains maximum security against virus attacks and user faults at every system start-up and turn-off. Data transfer is available via network connection or USB interface.

Infinite number of profile dimensions and properties can be stored. Automatically back-up daily data on internal storage unit. With shift monitoring system, all operations can be controlled daily, weekly, monthly and yearly. Central lubrication system to eases the machine maintenance. The rails are specially coated to prevent corrosion.