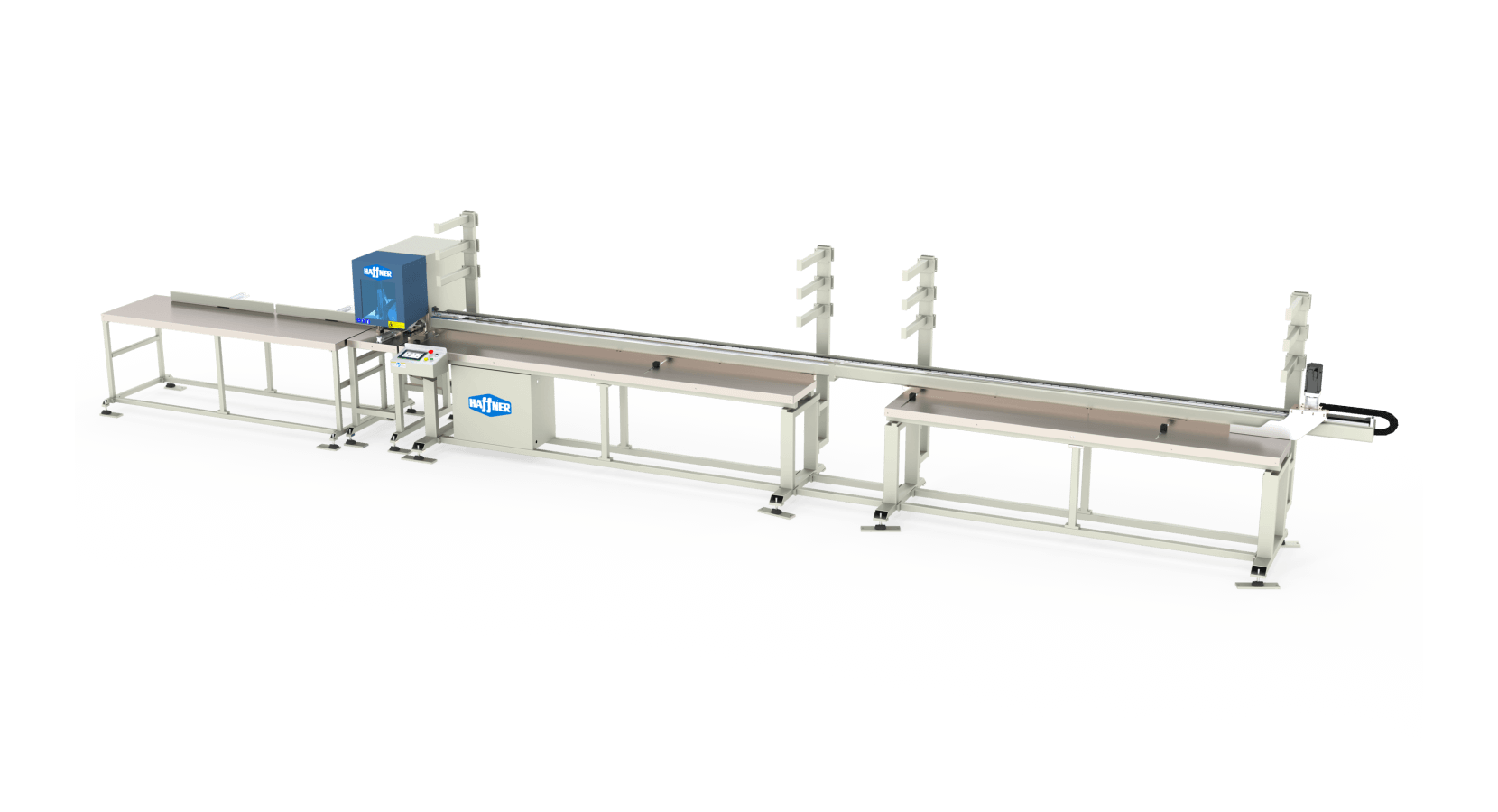

RC 600 Reinforcement Steel Profile

RC 600 Reinforcement Steel Profile Cutting Center is designed to perform computer- controlled cutting of reinforcement steel profiles used in PVC profiles in a single station. In this way, production speed and quality standardization are ensured by automatically pre-cutting the reinforcement steels in lengths suitable for PVC profiles ans at the same time labor costs effectively reduced.

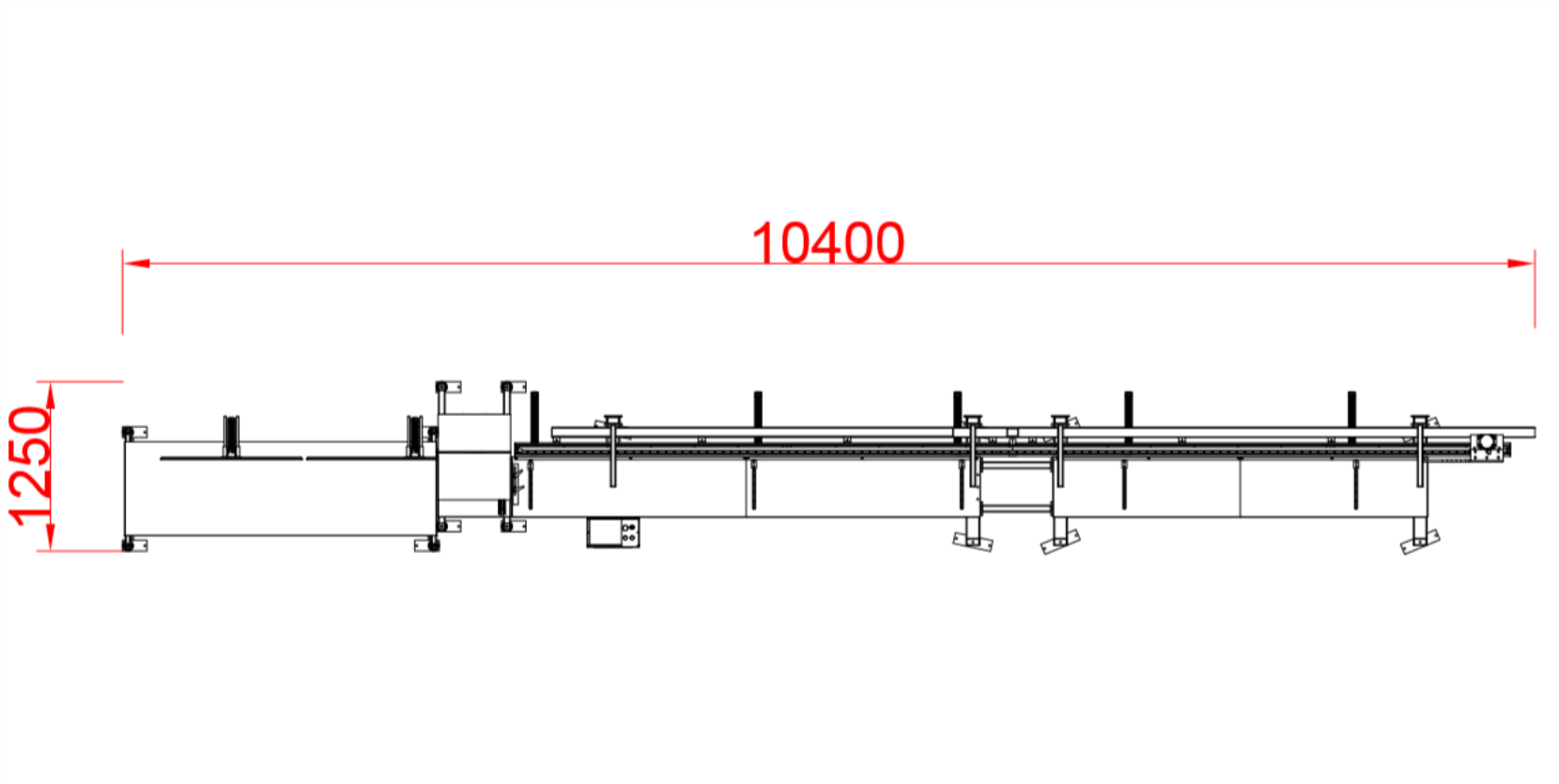

RC 600, which can also work in integration with the Machining Centers, can cut reinforcement steel simultaneously with the PVC profiles that cutting and milling operations are completed. RC 600 Reinforcement Steel Profile Cutting Center allows stacking of 5 pieces of steel profiles up to 6500 mm the loading belt. Thanks to the servo motor controlled profile pusher that can be positioned horizontal automatically, precise cutting is provided. The PLC controlled 7 ”touch screen on the RC 600 Reinforcement Steel Profile Cutting Center is used with a user-friendly interface developed by Haffner. The profiles to be cut can be displayed on the PLC screen and the cuts can be adjusted manually on the screen.

The system is integrated with door and window software of different brands. All data can be transferred to the machine using the USB port. Profiles are fixed in the best way with horizontal pneumatic compression pistons and milling and cutting processes are provided with minimum tolerance. The horizontal saw with a diameter of 420 mm in the RC 600 can easily cut even large steel profiles automatically. Cutted profile parts are transferred to the exit station. The waste parts measured at this station are included in the production again by informing the operator if they are suitable for re-used. The waste parts that cannot be used after cutting are automatically transported to the exit station. Optional Barcode Printer (AK 003) can be used in RC 600 Support Sheet Cutting Center. In this way, if not used simultaneously with Machining Centers, pre-cut support sheets can be prepared for production.