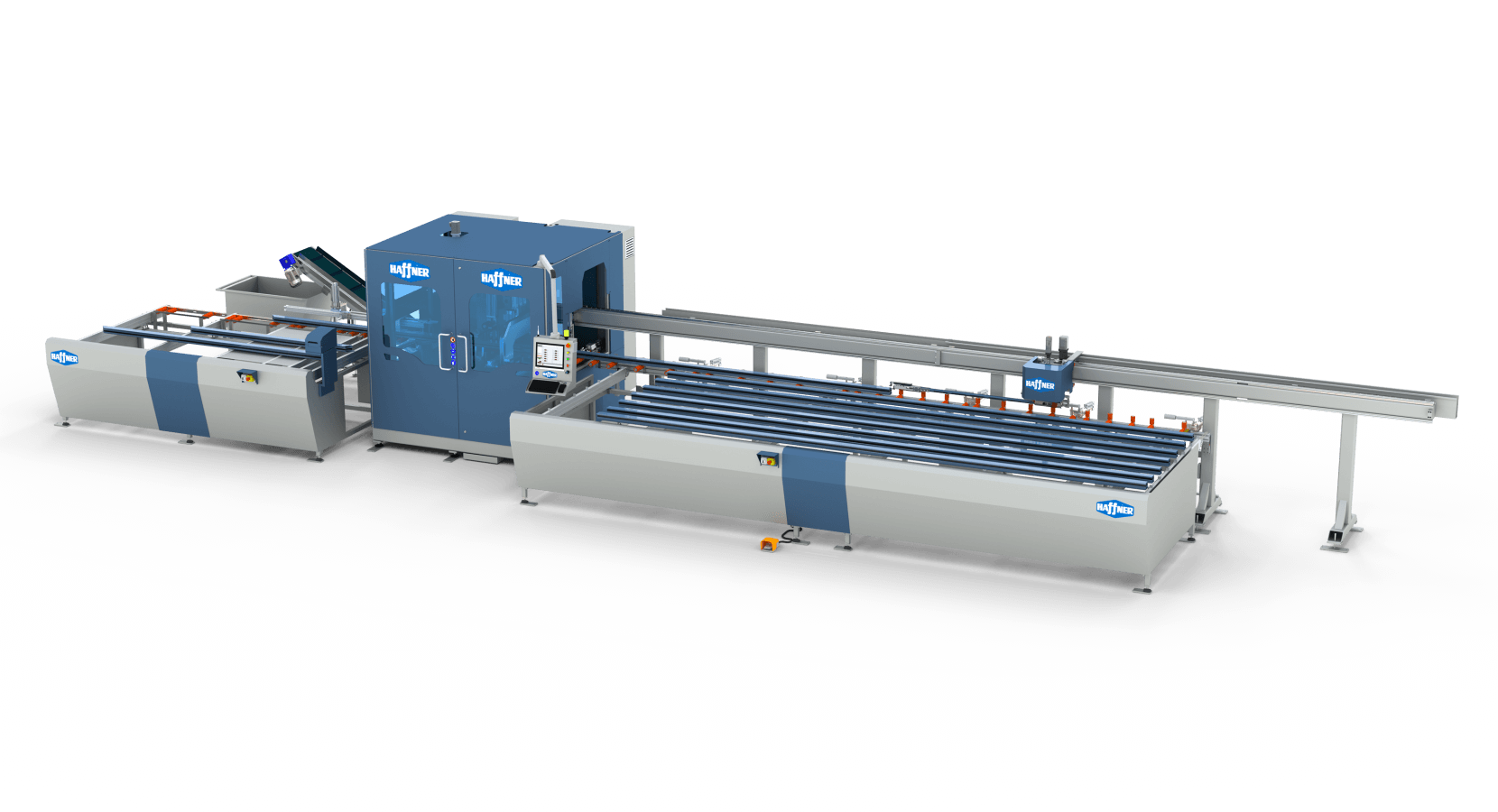

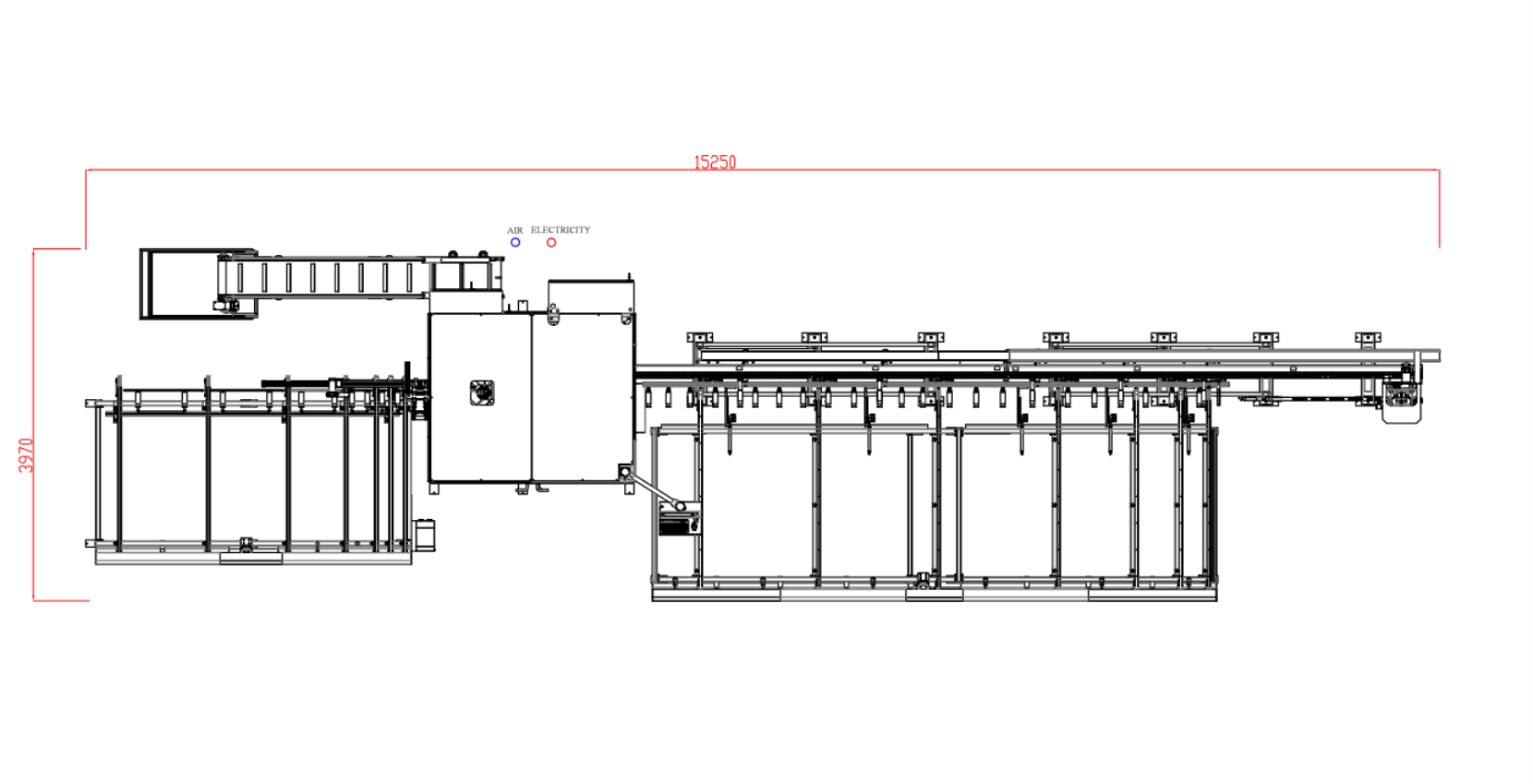

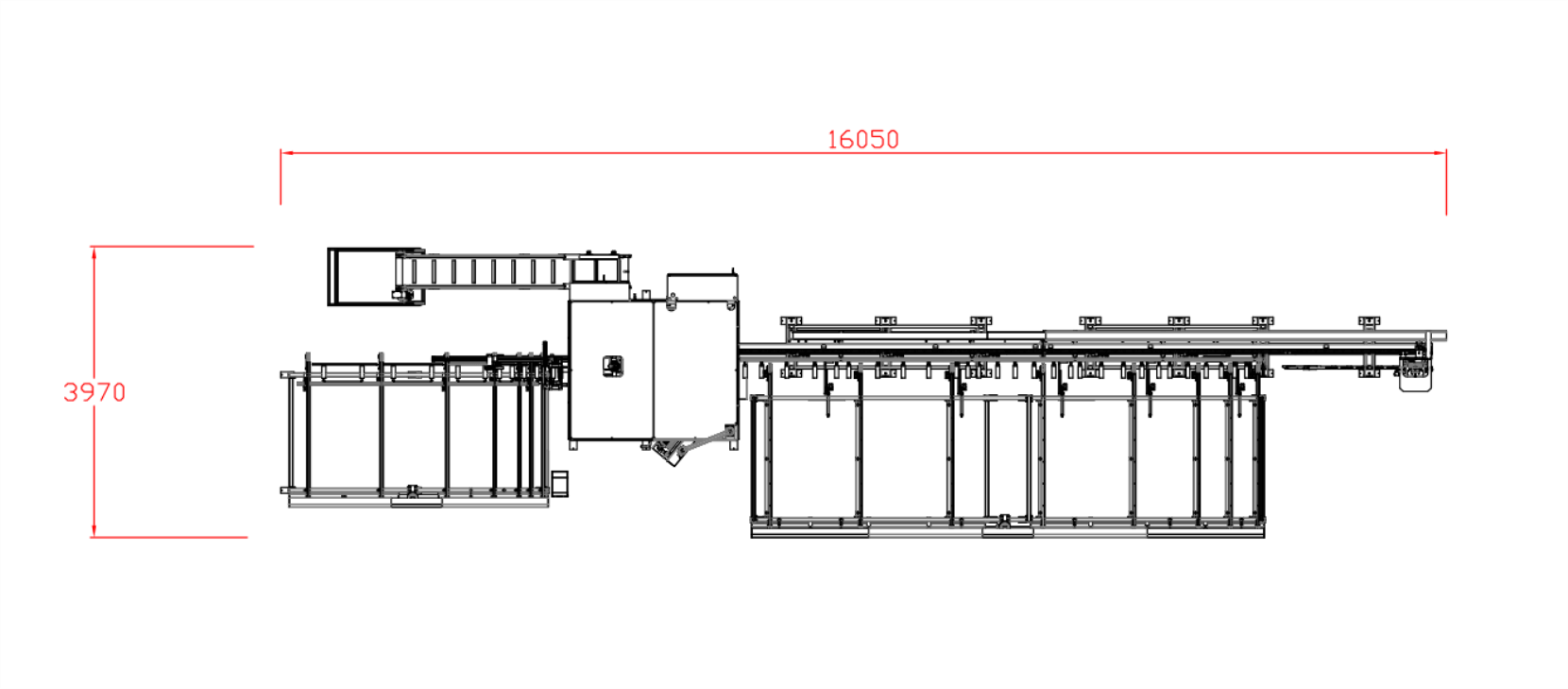

AL 220-80Aluminium Profile Machining Center

AL 220/80 Aluminium Profile Machining Center is designed to perform all cutting, milling, drilling and marking operations on aluminum profiles in a single machine with computer control. In this way, the operations performed on more than one cutting machine are collected in a single machine, ensuring production speed and quality standardization, at the same time, reducing labour cost.

AL 220/80 Profile Processing Center offers the possibility to stack up to 7 profiles up to 7000 mm on the loading belt. The servo motor controlled profile holder, which can be automatically positioned horizontally and vertically, has the ability to hold profiles of different designs and sizes and drive them into the machine. Thanks to the sensor on the profile holder, the lengths of the profiles placed on the loading belt can be measured automatically. AL 220/80 Profile Machining Center, ergonomic, 15.6 ”sized, high performance industrial PC with Windows 10 system, works without fan between 0 ° C - 55 °C connected to the machine with a movable arm rotating around machine and its own axis. It is used with a user-friendly interface developed by Haffner. The profiles to be milled and cut can be viewed on the screen in 3D. It can work in integration with facade, door and window software belonging to different brands and optionally it can also connect with SolidWorks.

Apart from these connections, data can be transferred to the machine using the USB port.

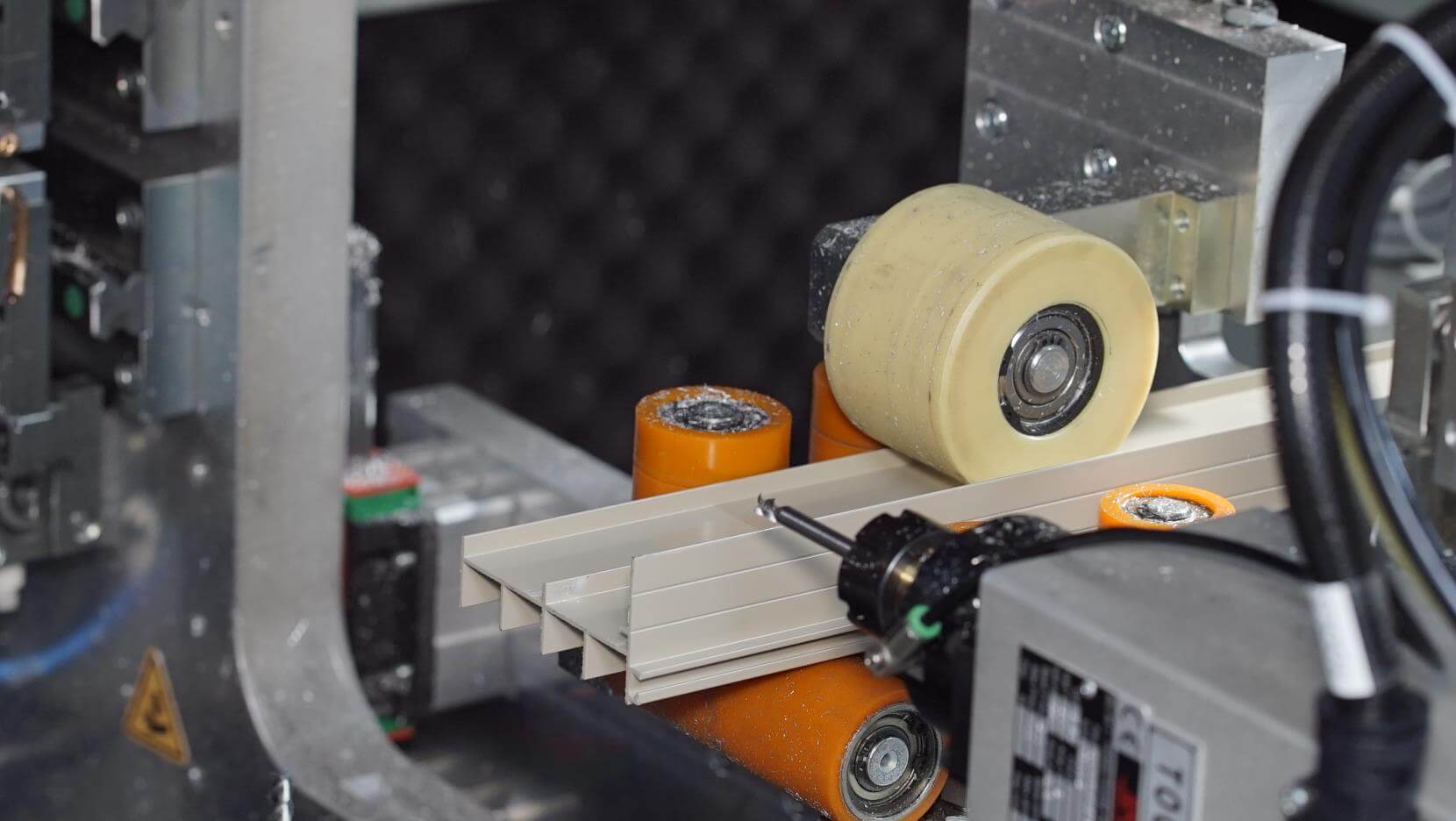

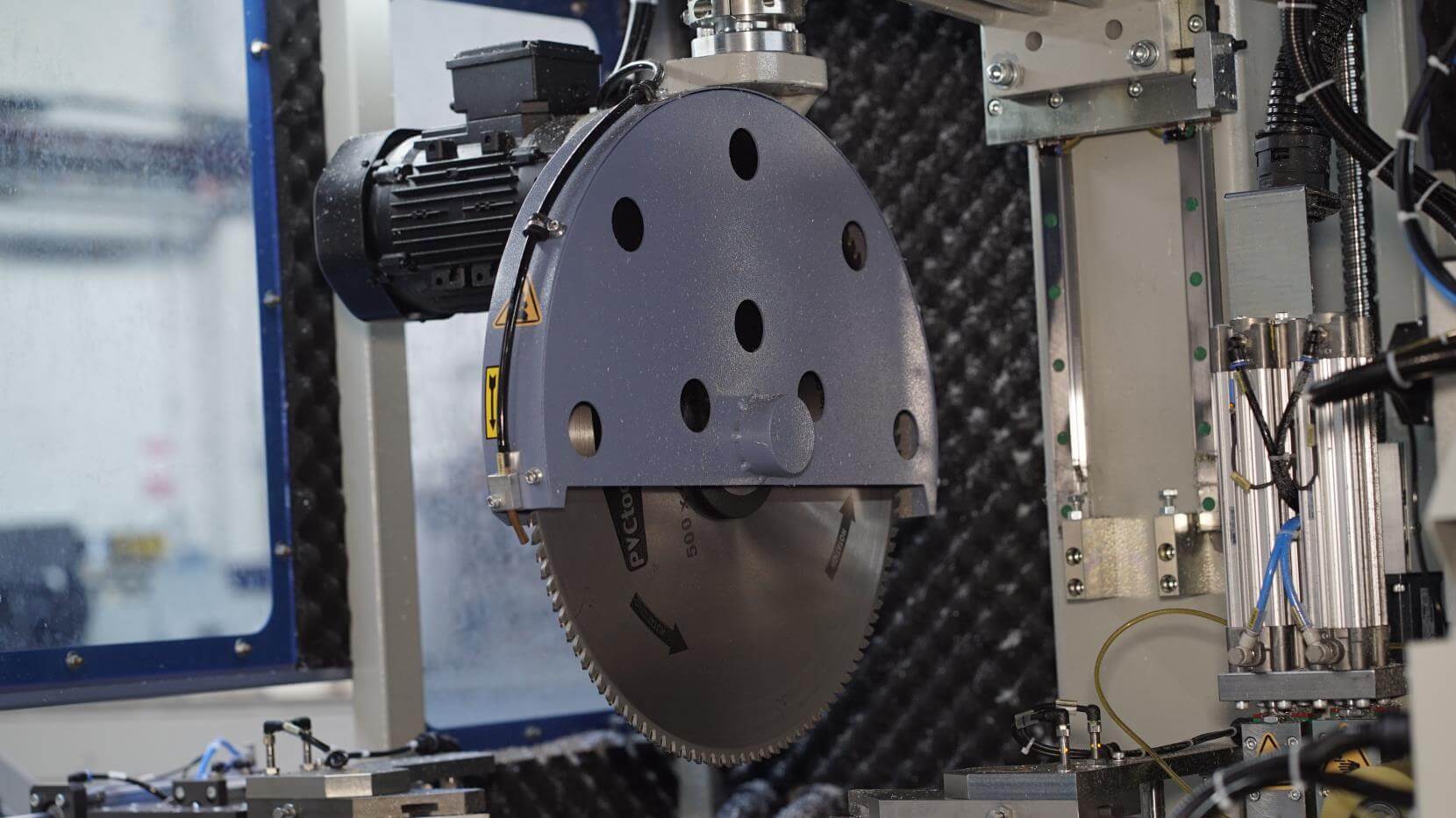

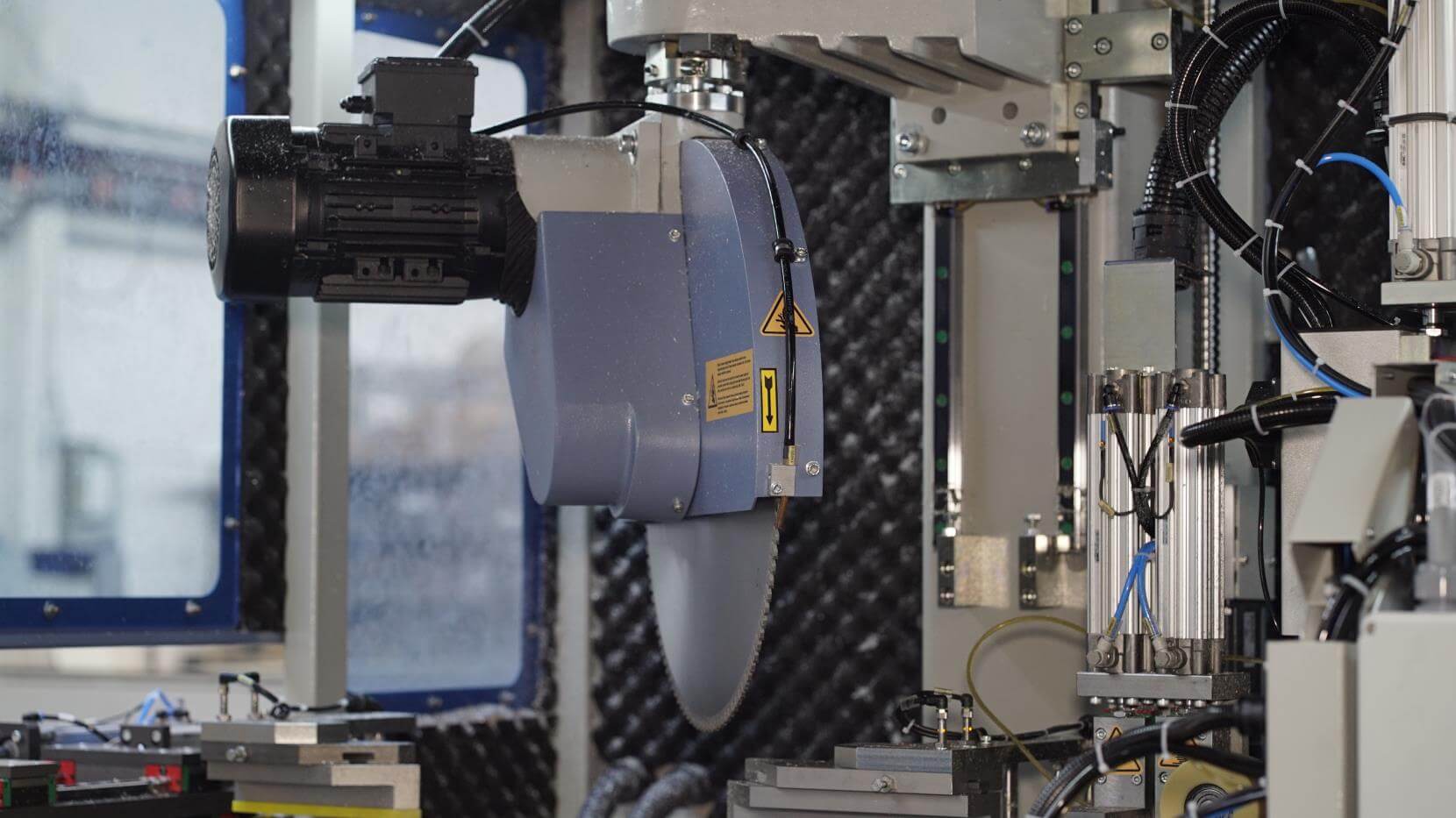

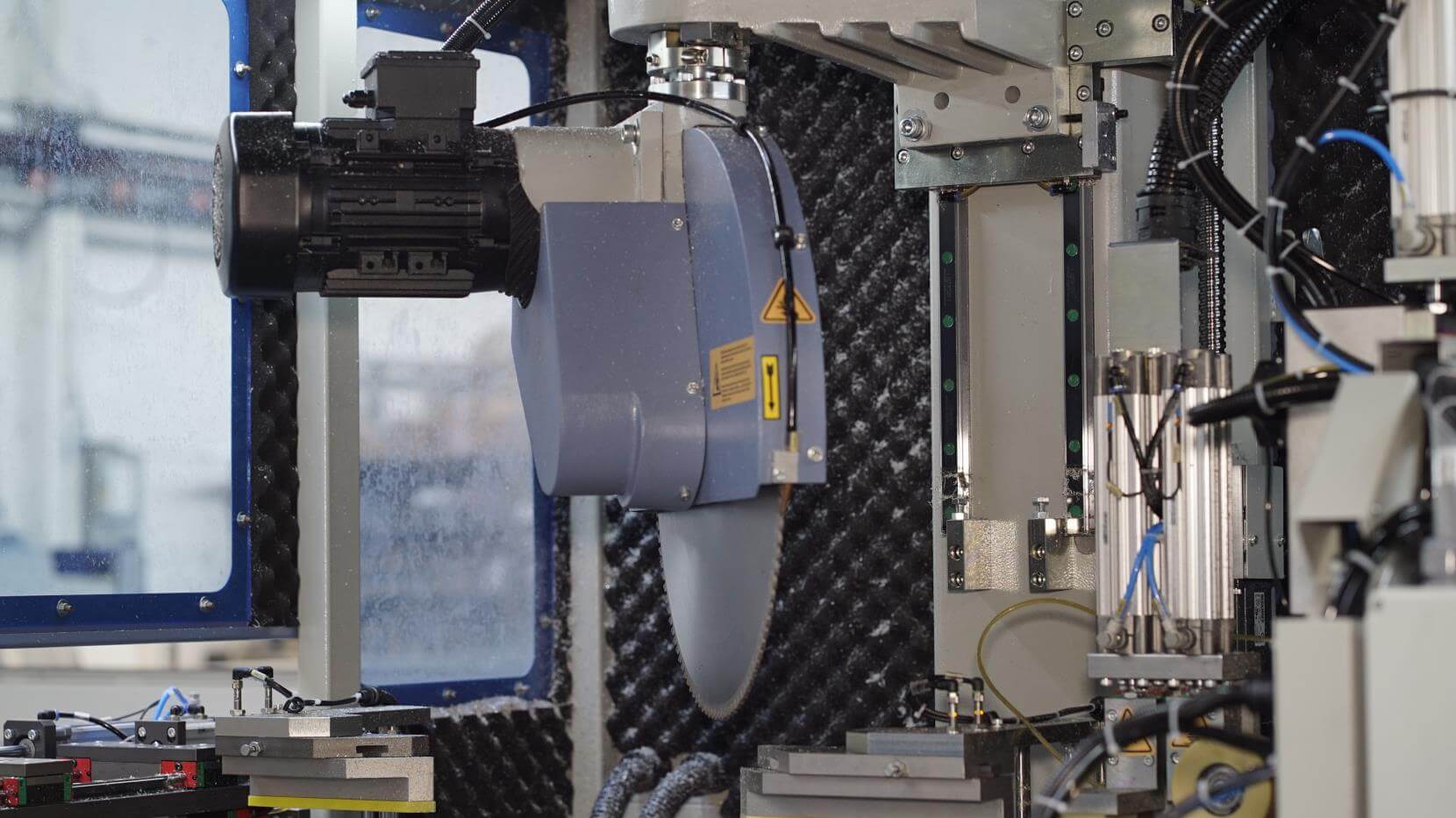

With both vertical and horizontal pneumatic clamping pistons, the profile is fixed in the best way and milling and cutting operations are provided with minimum tolerance. It performs all operations on the profile with maximum precision with 12 standard tools on the milling group. Thanks to the milling group that can move in 8 axes, it is possible to open drain slot, perform drilling and milling operations on the profiles with maximum flexibility with special router bits. Thanks to servo motors, the vertical saw with a diameter of 600 mm with 0.1 mm precision can automatically cut at all angles between 45 ° and 135 °. Axes controlled by servo motors work at high speed and precision, ensuring a superior cutting result.

Cutted parts are automatically transferred to the exit station by the holding system.

Profile parts lined up on the conveyor belt at the exit station and automatically transported to the operator.

The barcode printer system, which works in integration with the machine, simultaneously prints barcode on the label to be attached to the profile parts transfered to the operator.

Labels with barcodes are manually pasted on the profiles by the operator. Waste parts are transported to the waste chamber by the automatic conveyor system. AL 220/80 Profile Processing Center provides remote control and problem detection & solution by connecting to the entire automation system.

The operating system automatically cleans the unnecessary processes of the last session at every startup and shutdown of the machine, ensuring maximum security measures against virus and user errors. Daily backup is done automatically to the internal backup unit. The system provides the opportunity to control the production daily, weekly, monthly and yearly with the shift control system. There is a central lubrication system that facilitates machine maintenance.